- Home Page

- Company Profile

-

Our Products

- Pharmaceutical intermediates

- Water Treatment Chemicals

- Anionic Polyacrylamide

- Non-ionic Polyacrylamide

- Zwitterionic Polyacrylamide

- BCDMH Bromine Tablets

- Cationic Polyacrylamide

- Calcium Hypochlorite 70%

- CHA (Cyclohexylamine)

- Cyanuric Acid ( CYA )

- Chlorine Dioxide

- Sodium Hypochlorite

- Dichloroisocyanuriazc Acid Sodium Salt (Abbreviation: SDIC)

- Trichloroisocyanuric acid (abbreviation: TCCA)

- Drilling Fluid Drilling Mud Chemical

- Inorganic Chemicals

- Muriate of Potash

- Caustic Soda Flakes 99.0%

- Chlorinated Polypropylene ( Cpp)

- Soda Ash Dense 99.2%

- Melamine 99.8%

- Soda Ash Light 99.2%

- Sodium Bicarbonate Industrial Grade 99.0%

- Sodium Silicate Solid/ Solutions/ Powder

- Sodium Bicarbonate Feed Grade 99.0%

- Caustic Soda Pearls 99.0%

- Sodium Nitrate

- Sodium Nitrite

- Ammonium Chloride Industrial Grade

- Ammonium Chloride Reagent Grade

- Ammonium Chloride Battery Grade

- Ammonium Chloride Feed Grade

- Ammonium Chloride Electroplating Grade

- Ammonium Nitr ate

- Dimethyl Disulfide

- Food Additives Products

- Sodium Metabisulfite

- Theophylline Andydrous

- Phosphoric Acid ( H3PO4 )

- Food Grade Sucralose

- Hydrogen Peroxide

- Acesulfame Potassium

- Cmc Food Grade

- Sodium Bicarboante 99.0%

- Caffeine Anhydrous

- Calcium Chloride Flakes 77%

- Ammonium Chloride

- Aminophylline Powder

- Pentoxifylline CAS 6493-05-6

- Ethyl Maltol

- Sorbic Acid

- Potassium Sorbate

- Dehydroacetic Acid

- Diprophylline

- Theobromine Powder

- Bromide Chemicals

- Silica Gel

- CMC

- News

- Contact Us

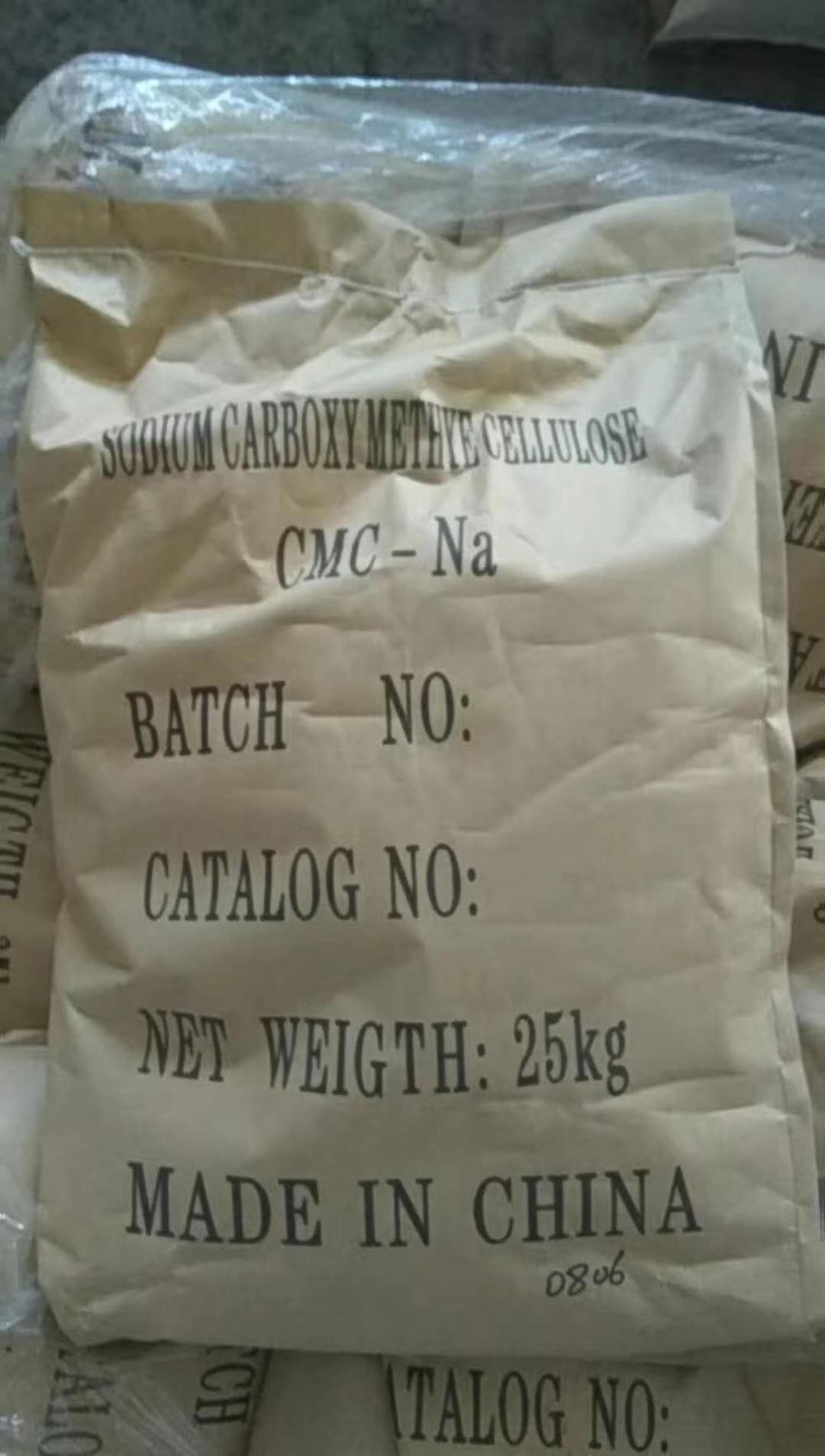

CMC Ceramic Grade

1000.00 - 2600.00 USD ($)/Ton

Product Details:

- Usage for ceramics

- EINECS No 265-995-8

- Appearance white powder

- CAS No 9004-32-4

- Storage Room Temperature

- Purity 99%min

- Click to View more

X

CMC Ceramic Grade Price And Quantity

- 1000.00 - 2600.00 USD ($)/Ton

- 300 Ton

CMC Ceramic Grade Product Specifications

- white powder

- 9004-32-4

- Room Temperature

- for ceramics

- 265-995-8

- 99%min

CMC Ceramic Grade Trade Information

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100-5000 Ton Per Month

- 20 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- kraft paper bag,each net in 25kgs,15000kgs with 20pallets in 1FCL(20")

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email