- Home Page

- Company Profile

-

Our Products

- Pharmaceutical intermediates

- Water Treatment Chemicals

- Anionic Polyacrylamide

- Non-ionic Polyacrylamide

- Zwitterionic Polyacrylamide

- BCDMH Bromine Tablets

- Cationic Polyacrylamide

- Calcium Hypochlorite 70%

- CHA (Cyclohexylamine)

- Cyanuric Acid ( CYA )

- Chlorine Dioxide

- Sodium Hypochlorite

- Dichloroisocyanuriazc Acid Sodium Salt (Abbreviation: SDIC)

- Trichloroisocyanuric acid (abbreviation: TCCA)

- Drilling Fluid Drilling Mud Chemical

- Inorganic Chemicals

- Muriate of Potash

- Caustic Soda Flakes 99.0%

- Chlorinated Polypropylene ( Cpp)

- Soda Ash Dense 99.2%

- Melamine 99.8%

- Soda Ash Light 99.2%

- Sodium Bicarbonate Industrial Grade 99.0%

- Sodium Silicate Solid/ Solutions/ Powder

- Sodium Bicarbonate Feed Grade 99.0%

- Caustic Soda Pearls 99.0%

- Sodium Nitrate

- Sodium Nitrite

- Ammonium Chloride Industrial Grade

- Ammonium Chloride Reagent Grade

- Ammonium Chloride Battery Grade

- Ammonium Chloride Feed Grade

- Ammonium Chloride Electroplating Grade

- Ammonium Nitr ate

- Dimethyl Disulfide

- Food Additives Products

- Sodium Metabisulfite

- Theophylline Andydrous

- Phosphoric Acid ( H3PO4 )

- Food Grade Sucralose

- Hydrogen Peroxide

- Acesulfame Potassium

- Cmc Food Grade

- Sodium Bicarboante 99.0%

- Caffeine Anhydrous

- Calcium Chloride Flakes 77%

- Ammonium Chloride

- Aminophylline Powder

- Pentoxifylline CAS 6493-05-6

- Ethyl Maltol

- Sorbic Acid

- Potassium Sorbate

- Dehydroacetic Acid

- Diprophylline

- Theobromine Powder

- Bromide Chemicals

- Silica Gel

- CMC

- Reclaimed Rubber

- News

- Contact Us

CMC Toothpaste Grade

2300 USD ($)/Ton

Product Details:

- Ingredients Carboxymethyl Cellulose sodium salt

- Grade Toothpaste Grade

- Usage Improve texture, stability and consistency of toothpaste

- Density 1.5 Gram per cubic centimeter(g/cm3)

- Properties High viscosity, good water solubility, stabilizer, thickener

- Ph Level 6.5 8.5 (1% solution)

- Physical Form Powder

- Click to View more

X

CMC Toothpaste Grade Price And Quantity

- 2300 USD ($)/Ton

- 300 , , Ton

CMC Toothpaste Grade Product Specifications

- 39123100

- 9004-32-4

- Non-poisonous

- Odorless

- Soluble in water

- Granular or fine powder

- 99%

- Odorless, tasteless

- Used as thickener, binder and stabilizer in toothpaste

- Chemical

- 618-326-2

- 262.19 g/mol

- Store in tightly closed container, dry and cool place

- 2 years

- C8H15NaO8

- Decomposes

- 6.5 8.5 (1% solution)

- High viscosity, good water solubility, stabilizer, thickener

- Carboxymethyl group substituted cellulose

- Powder

- White or off-white powder

- Improve texture, stability and consistency of toothpaste

- Toothpaste Grade

- Carboxymethyl Cellulose sodium salt

- 1.5 Gram per cubic centimeter(g/cm3)

CMC Toothpaste Grade Trade Information

- 100-5000 , , Ton Per Month

- 20 Days

Product Description

Classification:

Chemical AuxiliaryAgent

CAS No.:

9004-32-4

Other Names:

cmc

MF:

[C6H7O2(OH)2CH2COONa]n

EINECS No.:

232-674-9

Purity:

99%

Place of Origin:

Hebei, China

Type:

Cellulose

Usage:

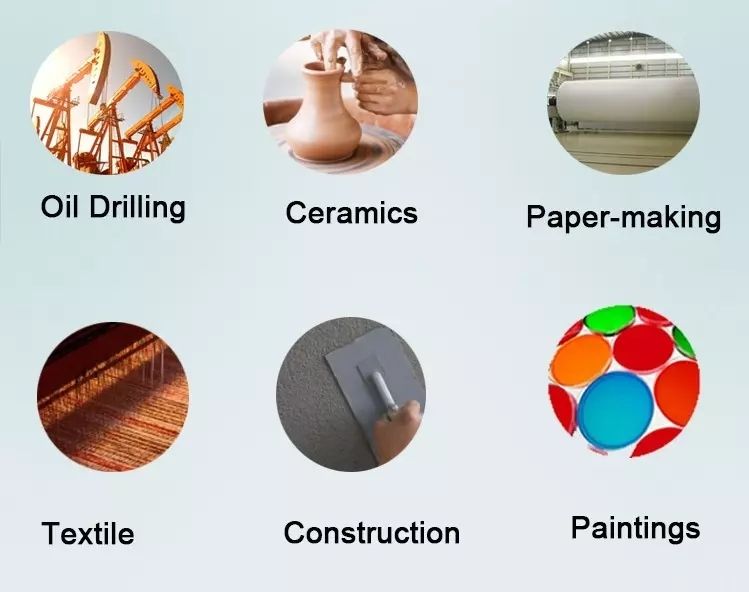

Coating AuxiliaryAgents, Electronics Chemicals, Leather Auxiliary Agents, Paper Chemicals,Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents,Surfactants, Textile Auxiliary Agents, Water Treatment Chemicals

Brand Name:

Cowin Industry

Model Number:

industry grade

Product name:

Industry GradeCarboxymethyl Cellulose CMC for toothpaste

viscosity:

200,000MAP.S

Color:

Sub-white,white

Grade:

industry grade

material:

cotton

low viscosity:

100,000mpa.s

Medium visocisy:

150,000mpa.s

function:

Thickening, gelling,adhesiving

Exceptional Thickening and Stabilizing Agent

CMC Toothpaste Grade enhances toothpaste texture by imparting high viscosity and excellent stabilization properties. Its consistent particle size and high water solubility ensure homogeneous blending, resulting in a smooth, stable product that resists separation over time.

Stringent Safety and Quality Standards

Our CMC fulfills global safety requirements, including a microbial limit below 1000 cfu/g and minimal heavy metal content. Each batch passes an 80 mesh sieve, ensuring a fine and uniform powder for optimal toothpaste formulation.

User-Friendly Storage and Shelf Life

Packaged in durable 25 kg HDPE bags with an inner liner, this CMC variant preserves its quality for up to two years when stored in cool, dry conditions. The packaging ensures ease of handling for manufacturers and consistent performance over prolonged storage.

FAQs of CMC Toothpaste Grade:

Q: How is CMC Toothpaste Grade used in toothpaste manufacturing?

A: CMC Toothpaste Grade is employed as a thickener, binder, and stabilizer in toothpaste formulations. It is typically dispersed in water and blended into the premix to improve the consistency, stability, and overall texture of the final product.Q: What are the main benefits of using high-viscosity CMC in toothpaste?

A: The primary advantages include enhanced viscosity, better suspension of active ingredients, improved stability against separation, and a smoother texture, all of which contribute to a superior consumer experience.Q: When should CMC be incorporated during toothpaste production?

A: CMC is usually introduced during the wet mixing stage, where it is dissolved in water before other components are added. This ensures even distribution and optimal thickening in the formulation.Q: Where should CMC Toothpaste Grade be stored for best results?

A: For maximum shelf life and quality preservation, CMC Toothpaste Grade should be kept in a tightly closed container, in a dry, cool place, away from direct sunlight and moisture.Q: What safety standards does your CMC Toothpaste Grade meet?

A: Our CMC meets strict safety parameters, including heavy metal content under 20 ppm, lead below 5 ppm, arsenic below 2 ppm, and a microbial limit under 1000 cfu/g, ensuring it is suitable for oral care applications.Q: How do I know the product will blend uniformly in my toothpaste batch?

A: CMC Toothpaste Grade passes through an 80-mesh sieve, resulting in a fine, granular or powder form that disperses readily in water, ensuring uniform blending in your toothpaste mixes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free